Digital HACCP 2026: the definitive blueprint for simple, safe and stress-free management

HACCP has never been easy.

Nor fast.

And definitely not rewarding.

For most teams, HACCP still means:

📌 Paperwork

📌 Incomplete records

📌 Stressful audits

📌 Duplicate tasks

📌 Hard-to-remember processes

📌 Endless reviews

But 2026 marks a turning point.

Because digital HACCP stops being “an interesting option”…

and becomes the new operational standard for food service, both for compliance and for scaling operations.

If you want to reach 2026 with real control, fewer errors, and stress-free audits, this is the definitive blueprint.

Digital HACCP 2026: the definitive blueprint for simple, safe and stress-free management

1. Digital HACCP = radical day-to-day simplification

The mistake of the past was trying to digitize HACCP exactly as it was, with all the same pain points.

2026 breaks away from that.

Modern digital HACCP:

- simplifies tasks

- reduces unnecessary steps

- automates controls

- eliminates duplicate records

- guides teams with clear micro-actions

This is not about “moving paper into an app”.

It’s about redesigning the system to be usable and scalable.

2. From manual records to automatic evidence

2026 will be the year the industry finally says:

“Enough with signatures, blurry photos, and unverified tasks.”

Digital HACCP requires:

✔ automatic records

✔ photo-based evidence

✔ role-based validations

✔ standardisation across locations

✔ tamper-proof history

This doesn’t just reduce errors – it creates a transparent, defensible operation for any audit.

3. Smart automation: tasks appear exactly when needed

Digital HACCP 2026 works like an operational assistant:

- triggers tasks by time

- shows only what matters for each role

- reminds teams of critical actions

- blocks inconsistent tasks

- alerts when something falls outside the standard

This turns the system into the foundation of operational consistency.

4. Integrated sensors: the connection that multiplies results

A modern digital HACCP system is incomplete without temperature sensors.

Integration enables:

- automatic temperature records

- 24/7 alerts

- trend analysis

- incident confirmation

- clean, reliable audits

The phrase of 2026 will be:

👉 No sensors, no real digital HACCP.

5. Smart expiration dates: a critical protection layer

Manually calculating shelf life was never reliable.

2026 demands absolute precision.

Digital HACCP includes:

- category-based smart logic

- automatic recalculation when products are opened

- system-generated labels

- centralised date control

This reduces human error and protects product quality.

6. Stress-free audits (finally)

Every auditor looks for three things:

- consistency

- continuity

- control

Digital HACCP 2026 gives you:

- clean records

- continuous data

- clear evidence

- full traceability

- one-click reports

The result: shorter audits, less tension, and better scores.

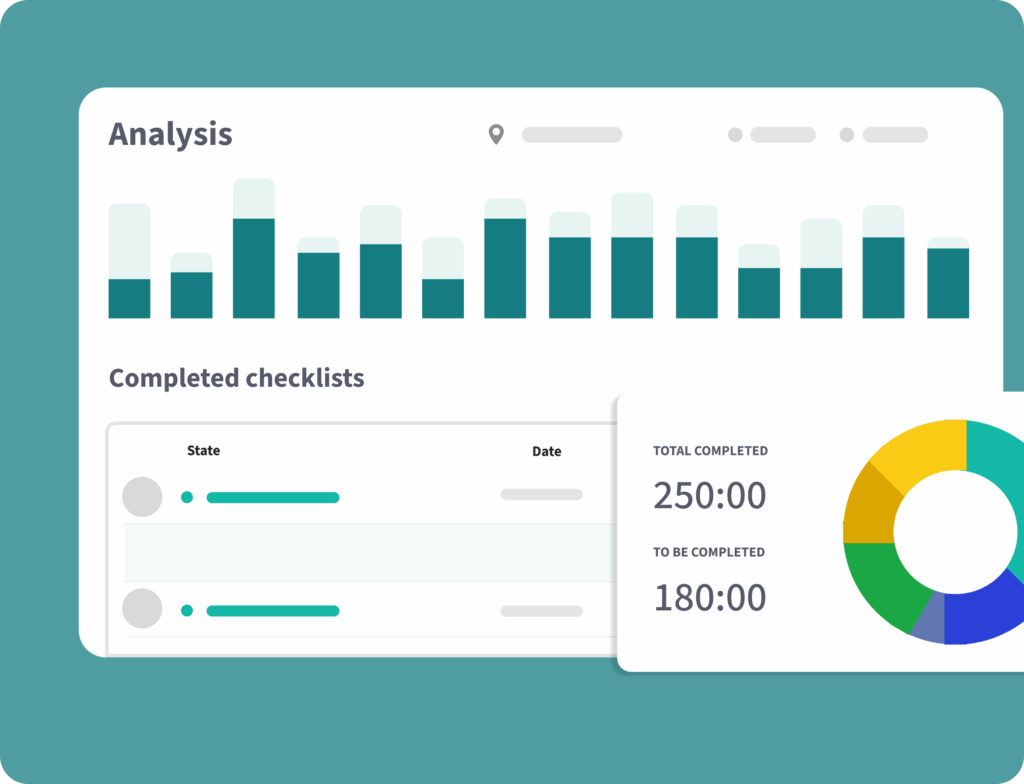

7. Multi-site operations become easier than ever

The biggest challenge for chains and groups has always been the same:

making sure every location does things the same way.

With digital HACCP:

- you standardize

- you see everything from a single dashboard

- you detect deviations quickly

- you apply coordinated corrections

- you ensure consistency at every site

2026 will be the year of unified systems.

8. Faster, clearer training with zero dependency

High staff turnover will remain the industry norm.

That’s why digital HACCP must work like an internal coach:

- guided tasks

- defined roles

- step-by-step instructions

- instant verification

- real-time feedback

This removes pressure from managers and guarantees consistency.

2026 demands clarity, traceability, and consistency.

And that only happens with systems that guide, verify, and automate.

HACCP is no longer a luxury or an optional project.

It is the backbone of any safe, scalable, and efficient operation.

Turn your digital HACCP into a competitive advantage.